InterfacePRO MES

It’s 10:00 AM – do you know where your cut is? Whether in your own factory or at a contractor’s factory? Are you learning about production problems before they become production hold-ups?

Can you examine the latest Spec Pack version at any point in your production? From any location in the world looking at any factory in the world? From your desk or your smart phone?

Manufacturing Execution Systems (MES)

orchestrate all production activities from the release of a Manufacturing Order through marking, spreading, cutting, bundling, sewing, QC packing and shipment. Making this happen requires the ability to obtain data and transmit data to all these operations. Hence our name: Interface Technologies.

At the heart of our software is our patent-pending Transaction Processor that can provide real-time interfaces to your existing systems. This means you can have full MES functionality up and running without lengthy programming or expensive system changes.

The “PRO” in our name stands for Productivity and Resource Optimization. Our suite of InterfacePRO software offers three modules to help you do just that.

.......................................................................................................................................................................................................................................

Production Tracking Module

Our Production Tracking module supplies all the information you need to run your plants at your fingertips… and right in front of those who need to know.

The browser-based software allows users to view the operations of any plant around the world, whether a company-owned manufacturing facility or a contractor site, depending on their authorization.

The built-in workflow provides clear steps for collaboration among work centers any combinations of routes and product groups. Product Specifications are instantly available to all users.

And the new Export to Excel function enables managers to filter and capture any real-time or historic data for analysis.

The Spread Consolidation Module is an expert system that will automatically sort planned Manufacturing Orders for garments into prioritized and consolidated groups of garments that can be spread and cut together and improve manufacturing productivity.

As domestic apparel manufacturers have moved to products offerings with higher-quality and higher margins but smaller production runs companies struggle with small Lot sizes that are inefficient to produce. This means they perform many one-time Job operations such as Marking, Material transport, Spreading, and Cutting over and over again instead of just once if the small Lots could be consolidated into a larger Job. Cut Job Consolidation will result in larger and more efficient batches of work.

Our Spread Consolidation software gathers production requirements earlier in the planning process and utilize inventory replenishment policies to gain a sufficiently large enough window of time for consolidation.

This technology was developed from a grant from the National Science Foundation for a feasibility study to determine whether we could use real-time data to achieve a productivity improvement of at least 20% in domestic apparel manufacturing. On the basis of a successful testing we were further awarded a Connecticut SBIR Acceleration and Commercialization Grant to turn our patent-pending algorithms into our Spread Consolidation Module.

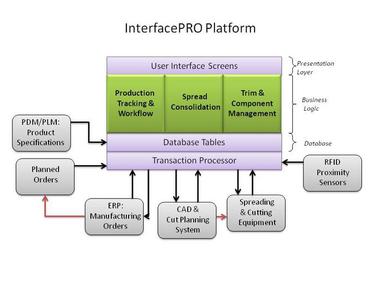

InterfacePro Platform

InterfacePro is the first Manufacturing Execution System per the ANSI/ISA-95 standard designed specifically for the unique needs of apparel manufacturing. The ANSI/ISA-95 standard defines the architecture of an MES in detail, covering how to internally distribute functionality and what information to exchange internally as well as externally.

InterfacePro is based on the WAMP architecture: Windows –Apache –MySQL –PHP. At the heart of the system is our Transaction Processor which provides real-time communication with other intelligent systems, such as ERP or CAD.

Internet architecture

InterfacePro can reside on a web server in the DMZ of a corporate information network or our secure cloud server. All users access the software through browsers via logon through secure Role-Based Authorization Control (RBAC). Departments and work centers around the world share date and collaborate on any mixture of routes as needed.

Spread Consolidation Module

Marking Automation Module

InterfacePro automates marking operations from receipt of Released Orders through planning, spread layout, bundling, ordering the markers and yield calculations.

The software provides:

- Cut Plans that incorporates fabric width, table length, desired section lengths, bundle constraints and minimizes end-loss.

- Spread Plans that are automatically populated with SKU, Fabric, Ply heights, Units/section and Marker information.

- Automatic Maker ordering of approved Spread Plans from most CAD systems.

- Cut yields that are automatically calculated when final ply heights are entered.

- Bundle numbering that is automatically adjusted when final ply heights are entered.

- Ability to manually adjust the Spread Plan and bundle numbers

- A Marking Workflow screen that shows the outstanding tasks for all Cuts at a glance.

- Order Bundle information screens that sewing supervisors can access to verify bundle and SKU allocation.